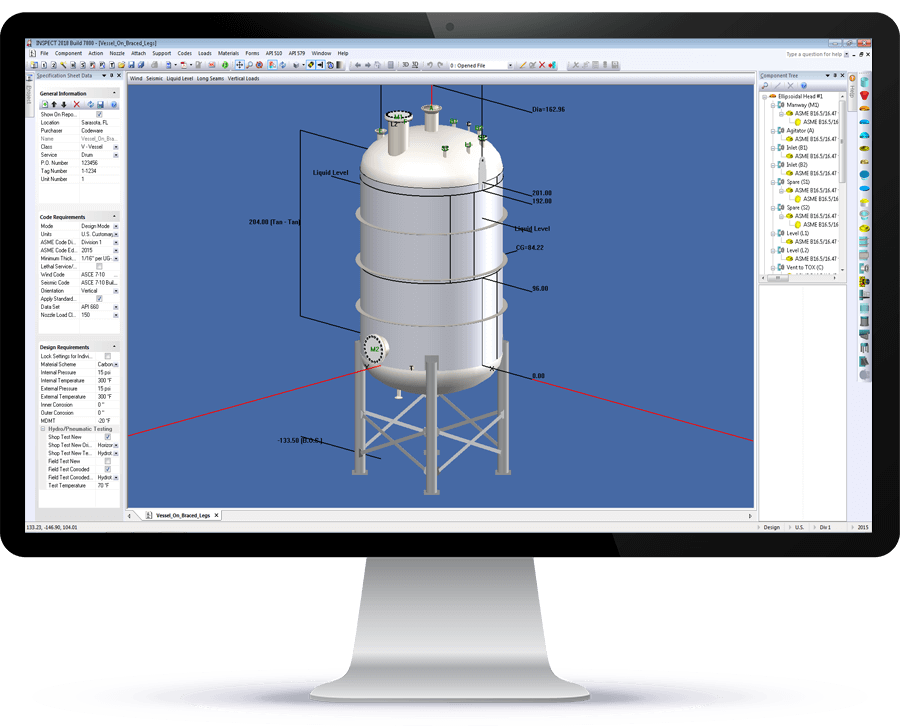

COSTER Import files from COMPRESS and create user. The COMPRESS Automatic Liquid Level feature saves time and reduces errors by eliminating the need to manually calculate the location specific static head for every nozzle flange shell.

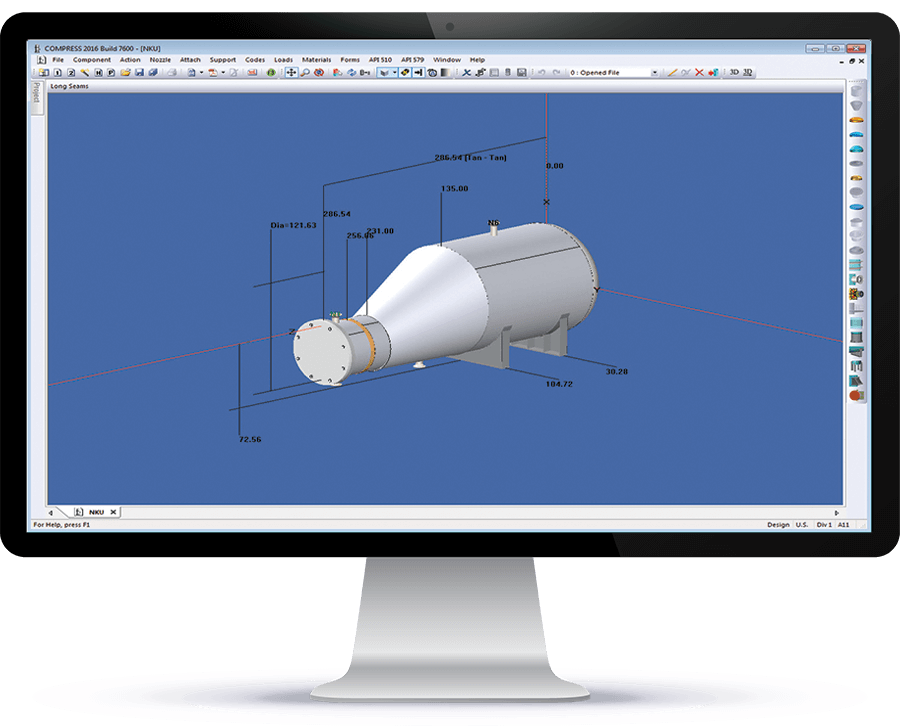

Pressure Vessel Software For Asme Viii Codeware

The design pressure of any pressurised container is the difference between the internal and external pressure.

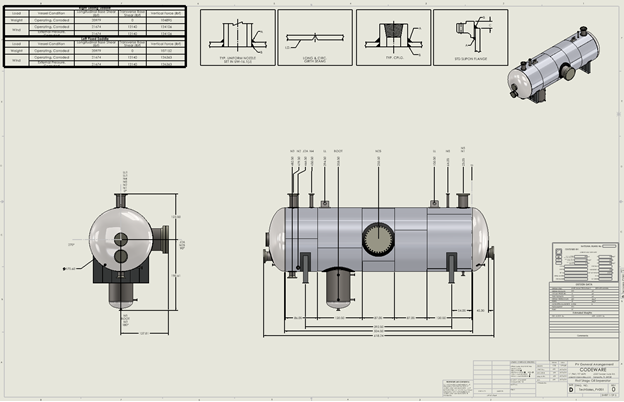

. Properly design a pressure vessel it is necessary to understand Section VIII of course and additionally the designer will need to be familiar with Sections II V. COMPRESS Pressure Vessel Design Calculations. The use of Compress IBC Seismic calculations and using SolidWorks for vessel drawing is discussed.

Compress is the most commonly used program for tower design in our office. Sign Up Now for the 2022 ASME Pressure Vessels Piping Conference. It performs comprehensive engineering calculations and allows you to quickly produce customized pressure vessel and heat exchanger design reports.

This is an existing Vessel that require to add a 8 sand KO we will need engineering and drawings for this addition. HYDROMATION FILTER MODEL FDB-170PVessel No. I would need time frame and hours to complete this job successfully.

Ad Discuss Industrial Challenges More at this Years Pressure Vessels Piping Conference. DESIGN CALCULATIONS OF PRESSURE VESSEL According to ASME Code Section VIII Division 1 Edition 2001 Addenda 2002 Designed by. Sign Up Now for the 2022 ASME Pressure Vessels Piping Conference.

Ad Discuss Industrial Challenges More at this Years Pressure Vessels Piping Conference. A big factor in this calculation is the unsupported length L. Static head Pressure resulting from weight of liquid Acting on.

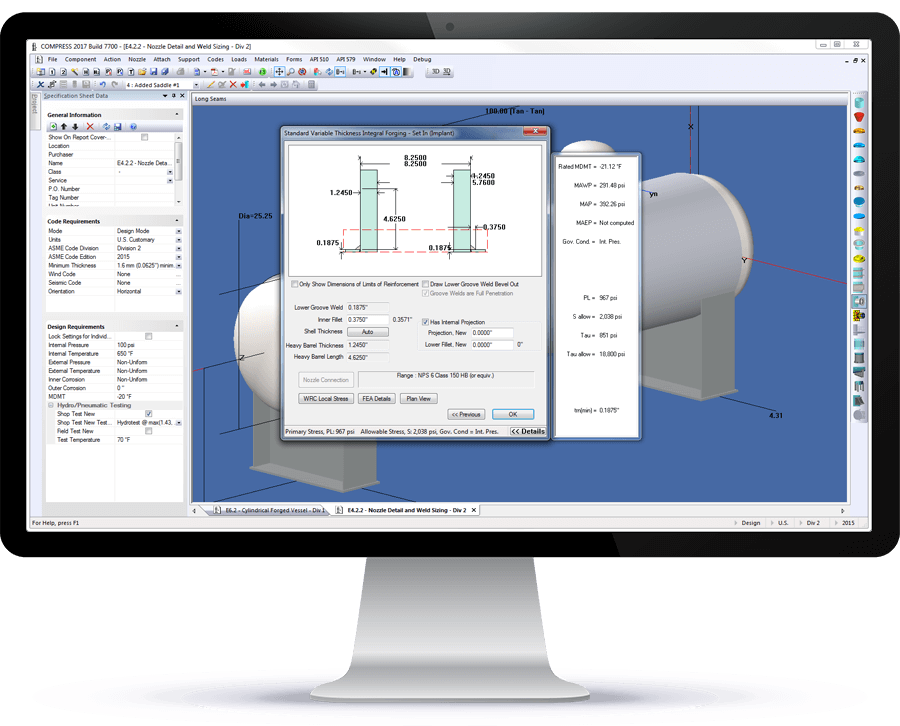

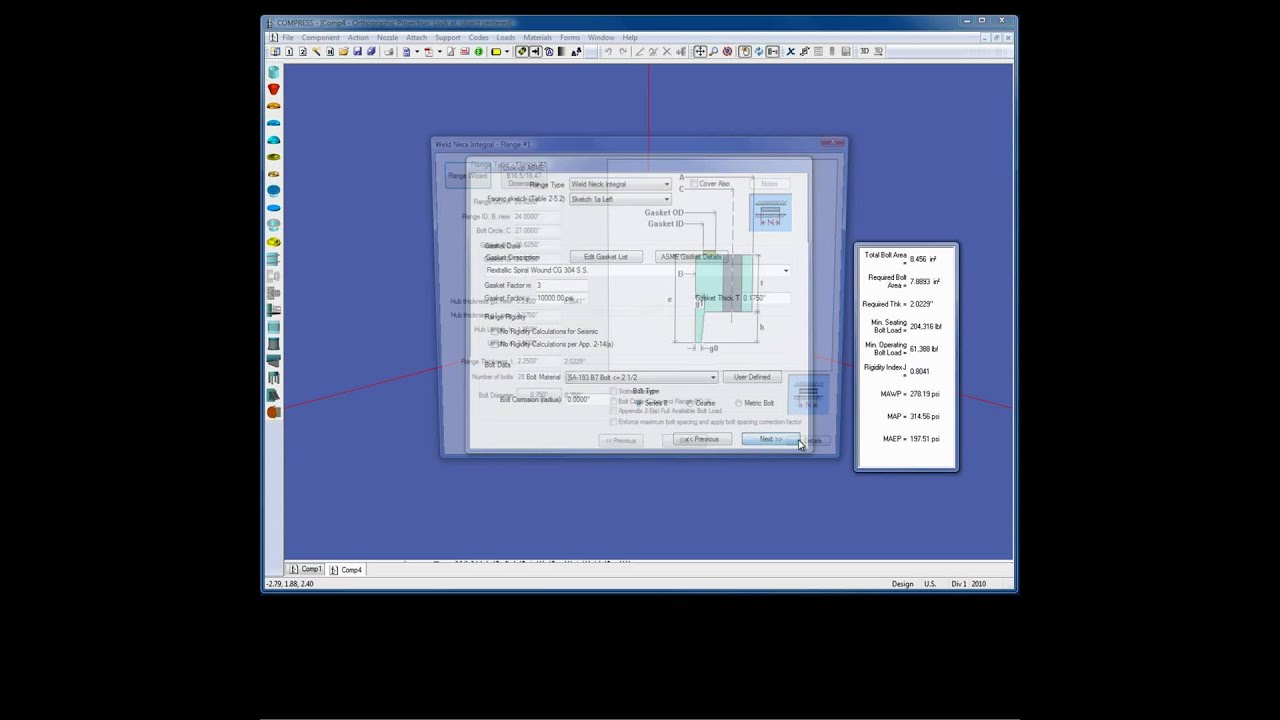

This vessel is calculated using the Compress pressure vessel code program by Codeware Inc. In the first example a pad reinforced nozzle on a cylinder is designed per UG-27 UG-37 UG-45 and UCS. Before the design is fully complete.

Design of vessel thickness. External pressure design is primarily a function of vessel geometry. Pressure Vessel Nozzle with Repad Design.

Thickness of Circumferential Shells Under Internal Pressure. Abdel Halim Galala Design General Manager. How to calculate static head in pressure vessel.

Pressure Vessel Nozzle Design Spreadsheet Calculator Design calculations for pressure vessel nozzle per. 4629 90 x 500 x 00362 30. Pressure vessel design to ASME VIII-1 and VIII-2.

The code calculations are performed using Pressure Vessel. Compress Pressure Vessel Design Calculations - ASME Search more Mechanical Engineering jobs Posted Worldwide This is an existing Vessel that require to add a 8 sand KO we will need. ASME Calculations - CRN Assistance - Vessel Design - Finite Element Analysis Design Conditions UG-22 Loadings Considered Pressure Vessel Engineering.

Design pressure of vessel includes. Design of Curved ends thickness. This 8ft diameter contact tank or retention vessel.

We have experience designing thousands of vessels and fittings to multiple codes. Is used for the. If external pressure is requiring vessel sections to get too thick.

UG-37 Appendix 1-10 1-7 and div 2. COMPRESS 2017 Build 7700 ASME Section VIII Division 2 2015 Edition Metric. Vessel Wizard The Vessel Wizard speeds pressure vessel design by creating complete pressure vessel models with minimal input.

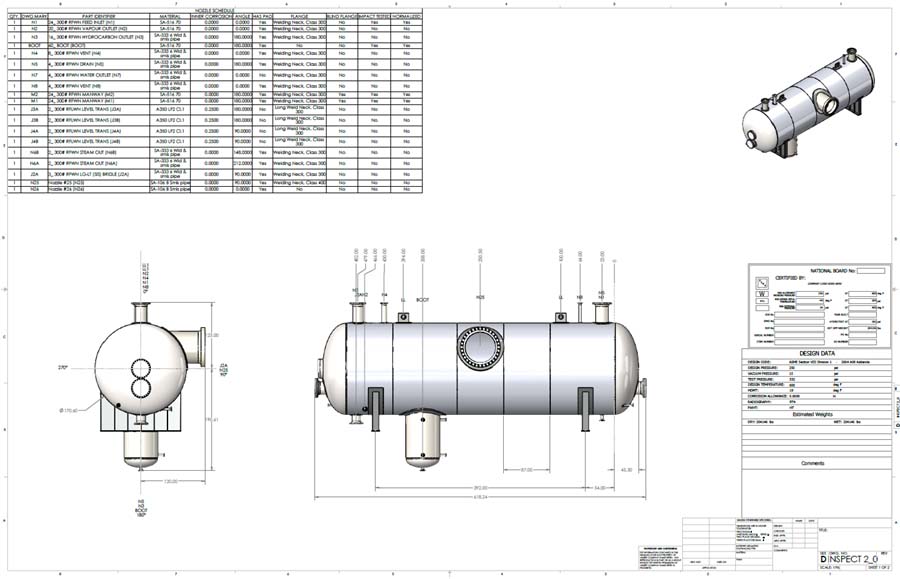

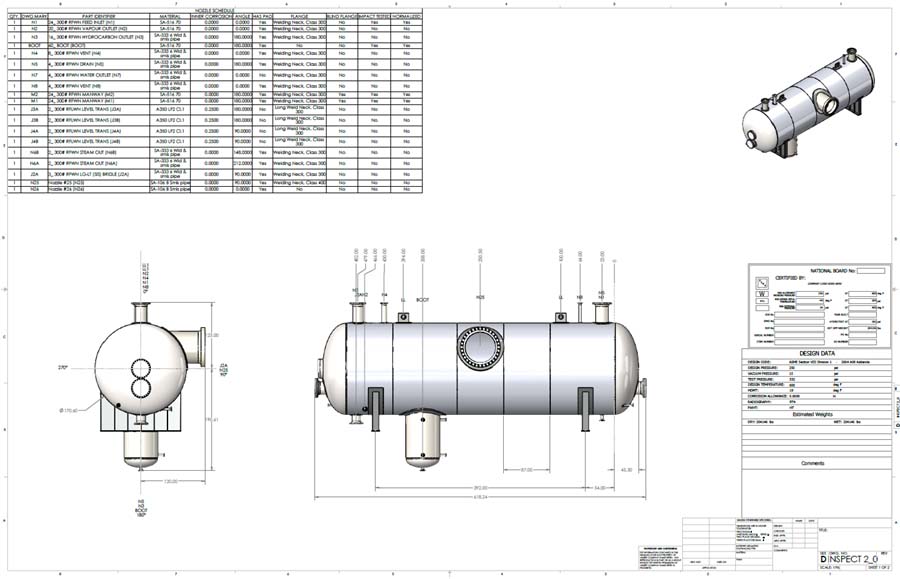

If a pressure vessel is exposed to an internal pressure of. Pressure vessel end cap designheads. The code calculations are performed using Pressure Vessel calculations Heat exchanger COMPRESS for each component of the vessel exchanger to calculate the minimum.

Hot water heaters and boilers to ASME I and IV. Pressure Vessel Engineering Ltd. The easiest way to design for external pressure is to make the shell thick enough to make the vessel stable with an acceptable factor of safety pass code calculations.

P Design Pressure internal psi R Inside radius of shell under consideration in S Max. Calculation of Hydrostatic Test Pressure. Heads shells large nozzles and special internals are quickly vetted and a vessel design summary sheet VDS is created from the calculations and passed.

See how to design two common ASME pressure vessel components in this video. Nominal t Vessel wall nominal thickness Design t Required vessel thickness due to governing loading corrosion Load Internal Circumferential stress due to internal pressure governs. The design of solid pressure vessel comprises.

Pressure Vessel Software For Asme Viii Codeware

Water Softener Vessel Pressure Vessel Engineering

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

Horizontal Retention Vessel Pressure Vessel Engineering

0 comments

Post a Comment